Pulse width adjustable laser marking machine(MZ-20M/MZ-30W/MZ-60M/MZ-100M/MZ-200M)

The reaction mechanism of laser processing is realized by photochemical ablation

1、Brief introduction of fiber laser marking machine

1)Equipment features

The reaction mechanism of laser processing is realized by photochemical

ablation, that is to say, the bonding between atoms or molecules is interrupted

by laser energy to make them vaporize and evaporate into small molecules. UV

laser marking has the advantages of small focusing spot, wide application

materials, processing materials that absorb red light, etc. Mainly used in

high-end market of fine processing.

The beam quality is good, the focus spot is smaller, and fine marking can be

realized;

Most materials can absorb infrared laser, so they are widely used to make up

for the lack of machining ability;

Strong adaptability, fiber laser does not need water cooler, and its

stability is much higher than that of traditional laser equipment;

Marking speed is fast and efficiency is high;

The whole machine has stable performance, small volume and low power

consumption.

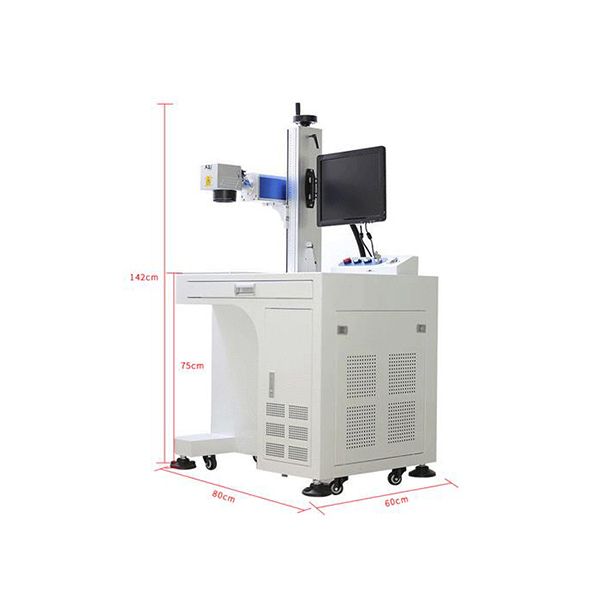

2、Equipment appearance

Dimensions: length 60cm * width 80cm * height 142cm;

(subject to the actual appearance)

1)Pulse width adjustable technical parameter

|

Model |

MZ-20M |

MZ-30M |

MZ-60M |

MZ-100M |

MZ-200M |

|

Maximum average laser power |

20W |

30W |

60W |

100W |

200W |

|

Laser repetition rate(Khz) |

1-4000 |

||||

|

Laser pulse width(ns) |

2-350 |

2-350 |

2-350 |

2-500 |

2-500 |

|

Laser wavelength |

1064nm |

||||

|

Beam quality M2 |

<1.4 |

||||

|

Standard engraving range |

100mm*100mm/150mm*150mm/175mm*175mm |

||||

|

Maximum line speed of engraving |

7000mm/s |

||||

|

Minimum line width |

0.05mm |

||||

|

Repeatability |

±0.03mm |

||||

|

Electricity demand |

220V±22V / 50Hz /10A/15A/18A |

||||

|

Power consumption of the whole machine |

<800W |

||||

|

working temperature |

0-40℃ |

||||

|

relative humidity |

<80% |

||||

2)Fixed pulse width type technical parameter

|

Model |

MZ-20W |

MZ-30W |

MZ-50W |

MZ-100W |

MZ-200W |

|

Maximum average laser power |

20W |

30W |

60W |

100W |

200W |

|

Laser repetition rate(Khz) |

27-80 |

20-200 |

|||

|

Laser pulse width(ns) |

80-120 |

80-120 |

80-120 |

150-270 |

150-270 |

|

Laser wavelength |

1064nm |

||||

|

Beam quality M2 |

<1.5 |

<2 |

|||

|

Standard engraving range |

100mm*100mm/150mm*150mm/175mm*175mm |

||||

|

Maximum line speed of engraving |

7000mm/s |

||||

|

Minimum line width |

0.05mm |

||||

|

Repeatability |

±0.03mm |

||||

|

Electricity demand |

220V±22V / 50Hz /10A/15A/18A |

||||

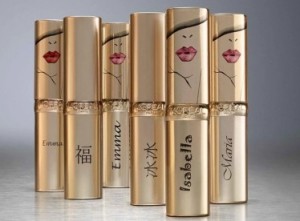

3. Sample Images

|

|

|

|

Mountaineering buckle carving |

Dog tag carving |

Logo carving |

|

|

|

|

Ring carving |

Cosmetics shell carving |

Aluminum carving |

4. Working Environment Requirements

1) Ambient temperature should be between 0-35°C, and air conditioning is

required;

2) Humidity should be between 45%-75%. No condensation is allowed, and a

dehumidifier should be installed;

3) Power supply requirements: 220V, 50Hz;

4) Power grid fluctuation: ±5%, and the grounding wire must comply with

international standards. In areas with voltage amplitude exceeding 5%, an

electronic automatic voltage and current stabilizer should be installed;

5) There should be no strong electromagnetic signal interference near the

installation site. Avoid radio transmission stations (or relay stations) in the

surrounding area;

6) Foundation vibration amplitude: recommended to be less than 50 µm;

vibration acceleration: recommended to be less than 0.05g. Avoid having a large

number of stamping or other machine tool equipment nearby;

7) The equipment space must be smoke-free and dust-free. Avoid environments

with severe dust, such as metal polishing or grinding;

8) Strict requirements for the quality of cooling water: purified water,

deionized water, or distilled water must be used. Tap water, mineral water, or

other liquids containing high levels of metal ions or minerals are not

allowed.

Related products

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs! -

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m -

FSH-FMI2020-B Standard Single/Double Channel Fluid Injection

Contact UsFSH – FMI2020 – B standard series of high-precision fluid dispensing / refilling system consists of a digital control box, stepper motor and one to two high precision rotary ceramic pump modules driven by step motor.

Reviews

There are no reviews yet.