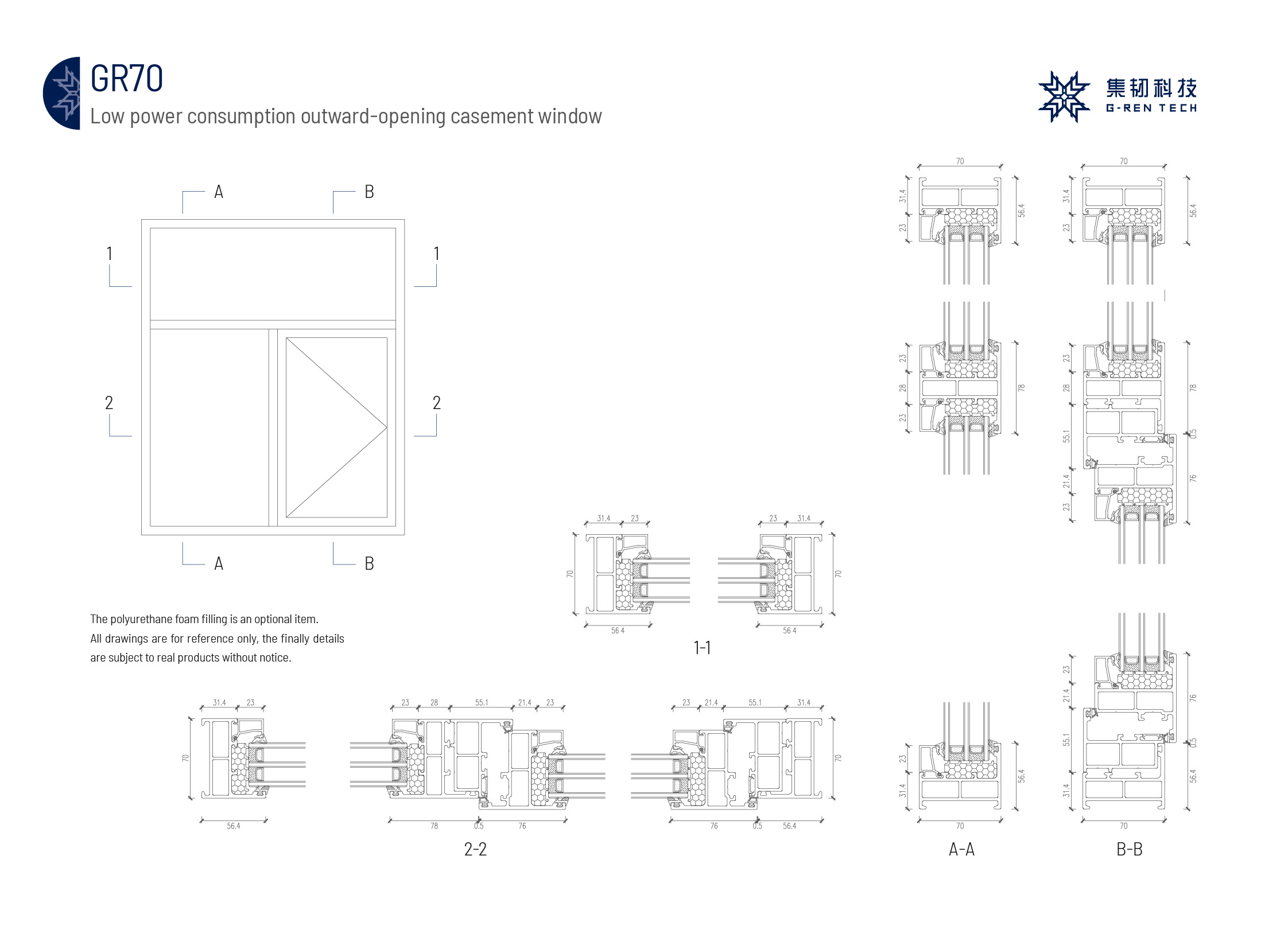

GR70 Low power consumption outward-opening casement window

Fiberglass reinforced polyurethane composite material is the high-performance composite material based on 20% polyurethane (PU) and 80% fiberglass (GF).

GR70 Low power consumption outward-opening casement window

Global door & window material innovation

Global door & window material innovation

Characteristics of PU fiberglass composites

| Property | Aluminum Alloy | Steel | R PVC | Fiberglass Reinforced Plastic | Fiberglass Reinforced Pu |

| Density (g/cm³) | 2.7 | 7.8 | 1.4 | 1.8 | 2.2 |

| Bending strength (MPa) | 170-230 | 200~500 | 70~110 | 300~600 | 1442 |

| Bending modulus (GPa) | 68 | 200 | 2.2~5 | 10~22 | 44 |

| Tensile strength (MPa) | 200~300 | <670 | 35~52 | 300~600 | 1220 |

| Tensile modulus (GPa) | 68 | 200 | 2.2~5 | 20~25 | 56.5 |

| Strength-weight ratio (10³N·m/kg) | 74~111 | <86 | 25~37 | 333 | 581 |

| Thermal Conductivity (W/m·K) | >150 | 36~54 | 0.14 | 0.4 | 0.114 |

| Linear expansivity (10-5K-1) | 2.2~2.4 | 1.2 | 6~7 | 0.7~6 | 0.5 |

| Volume resistivity (Ω·m) | 2.9*10-8 | 9.8*10-8 | 1*1011-12 | 1*1012 | 1.5*1012 |

| Corrosion resistance (acid, alkali, salt) | Poor | Poor | Averagely | Excellent | Excellent |

Polyurethane Glass Fiber Composite (PU-GFRP)

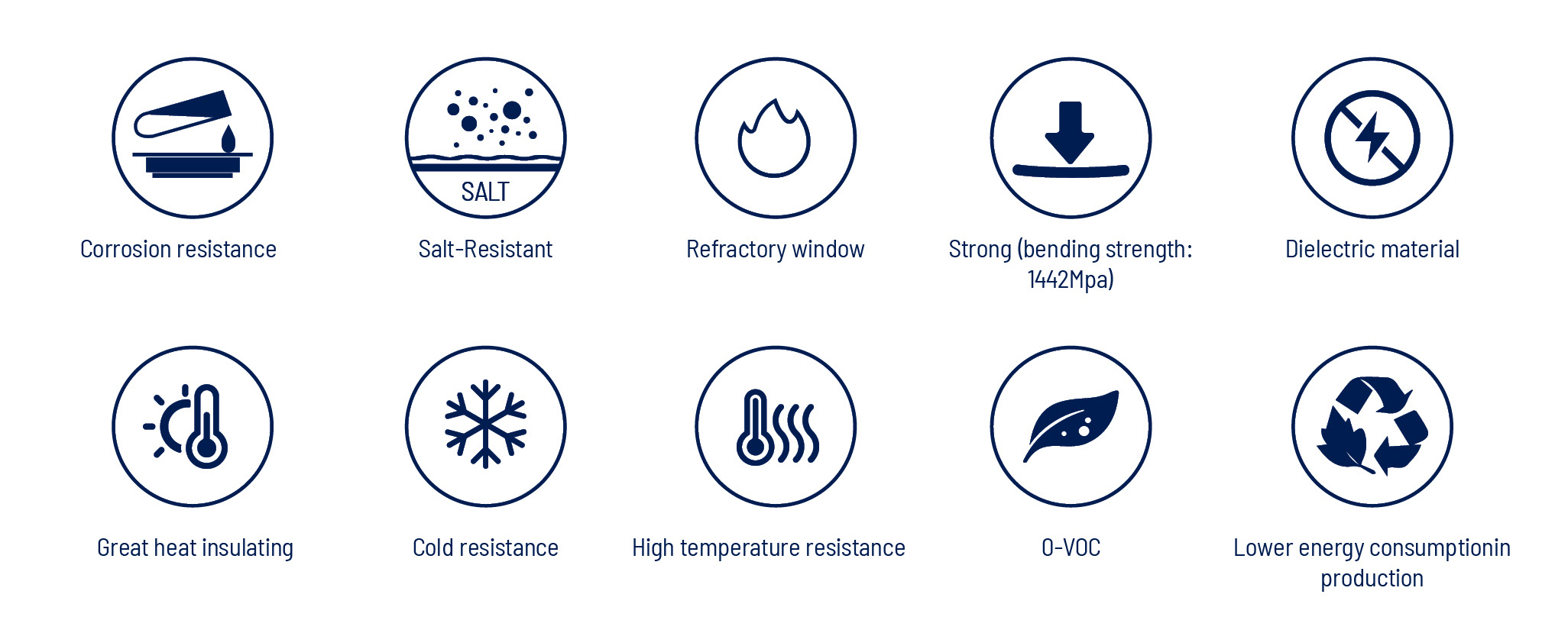

Lightweight & High Strength: Density is just 1/6 of steel and 1/2 of aluminum, yet delivers exceptional strength and toughness.

Superior Corrosion Resistance: Excels in harsh environments (salt spray, acids/alkalis, humidity).

High Design Flexibility: Formula adjustments enable customized hardness, elasticity, color, and surface textures to meet specific needs.

Fiberglass reinforced polyurethane composite material is the high-performance composite material based on 20% polyurethane (PU) and 80% fiberglass (GF).

PU fiberglass material combines the excellent toughness, fatigue resistance, impact resistance and processing flexibility of polyurethane resin, as well as the high strength, high rigidity and stability of fiberglass.

Formed through efficient processes such as pultrusion and winding, it features light weight and high strength, thermal insulation, corrosion resistance, and environmental friendliness, and its mechanical properties can be comparable to some metal materials.

Due to its many excellent properties, PU fiberglass composite material is widely used in multiple industrial fields such as door and window curtain wall systems, wind energy, photovoltaics, new energy vehicles, medical equipment, engineering equipment, aerospace, etc., and gradually replaces metal and traditional plastic materials.

Related products

-

BBQ for outdoor kitchen

Contact UsCrafted for the discerning grill enthusiast, this barbecue grill is engineered for durability and exceptional performance.

-

Single Slot Diffuser

Contact UsThe Tanto linear slot diffuser is engineered to meet architectural applications requiring continuous lengths without compromising air distribution performance.

-

SIP prefabricated building-Luxury Edition

Contact UsThe SIP (Structural Insulated Panels) structural insulated panel system is an innovative prefabricated building system composed of structural panels and insulation core materials.

-

Barbecue Egg

Contact UsThis vintage-inspired ceramic mini barbecue features a rounded black-veined ceramic body exuding rugged retro charm, offering both high-temperature resistance and even heat retention.

Reviews

There are no reviews yet.