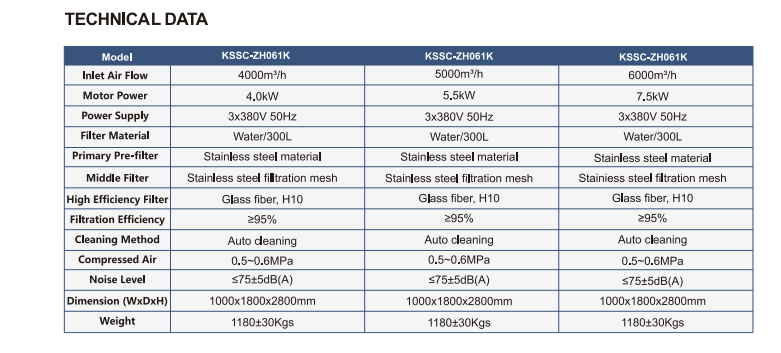

Kssc-zh061k Wet Grinding Dust Collector

It is main applied to flammable, explosive and big spark metal dust.

The air with dust entries into dust collector through suction inlet section under the fan working status, the bigparticles will drop into water tank bottom.

Function:

It is main applied to flammable, explosive and big spark metal dust.

The air with dust entries into dust collector through suction inlet section under the fan working status, the bigparticles will drop into water tank bottom.

The fine particles will pass the water wall is generated by stainless steel vortex coiler, and the fine particles are mixed with water and dropped into water tank bottom.

The V shape aluminum alloy water fender intercepts the fine water mist.

The stainless steel sintering mesh makes gas-liquid separation,PLC controls auto cleaning.

Two pieces glass fiber HEPA filter which purifies the tiny dust particles.

Related products

-

LCTW Dynamic pass box

Contact UsThe self-cleaning transfer window allows for the transfer of materials, utensils, and other items under Class A environmental protection. Items are self-cleaned within the window before entering areas of higher cleanliness. The self-cleaning transfer window is equipped with an ultraviolet sterilization lamp and can also be fitted with a royal oxygen sterilization system according to user requirements.

-

Waste liquid and waste gas incineration device

Contact UsThe furnace volume of the combined incinerator is based on the exhaust gas generated by incineration, the comprehensive residence time is ≥4s, the high-temperature (1100℃) incineration treatment is ≥1100℃, and the high-temperature section residence time is ≥2.5s to ensure the removal efficiency of organic matter.

-

Solid-liquid incinerator project for Ningxia

Contact UsThis project is a 10,000 tons/year hazardous waste incineration device for Ningxia, which is used for incineration and treatment of hazardous waste produced by our factory.

-

Metal sheet drying oven for can making

Contact UsThe oven is mainly used to dry the coating on the tin (or aluminum) sheet in the can making process. The entire line mainly consists of conveying, feeding devices, drying, cooling, and material collection and stacking.

Reviews

There are no reviews yet.