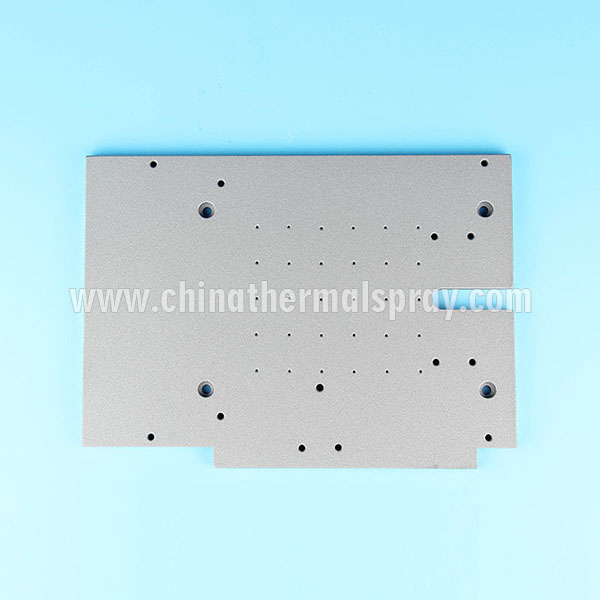

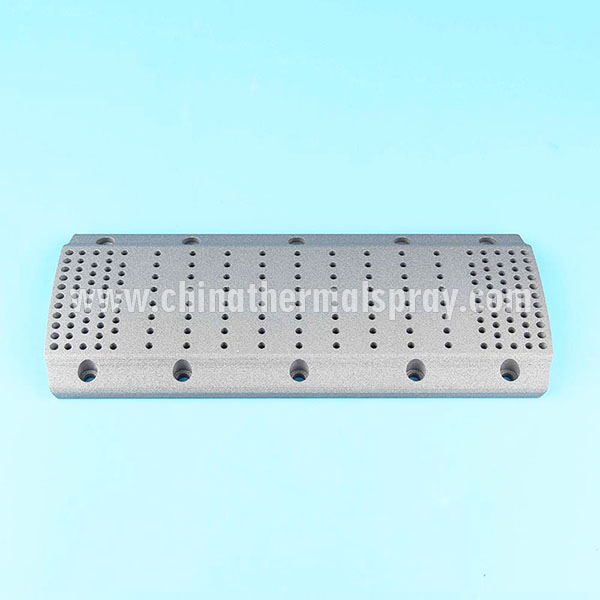

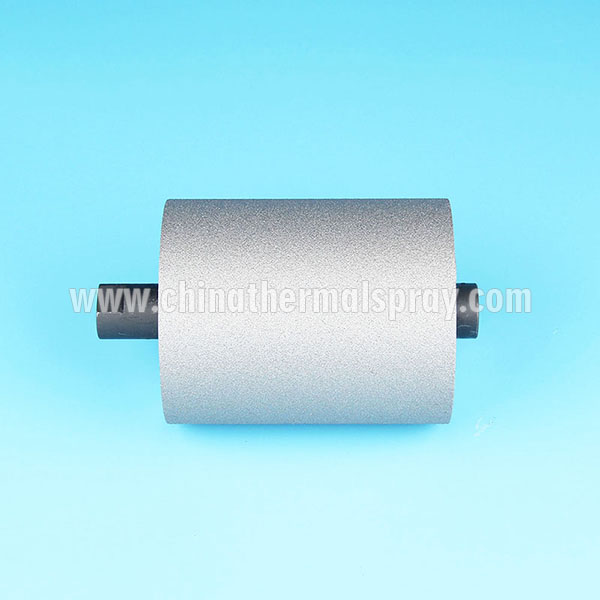

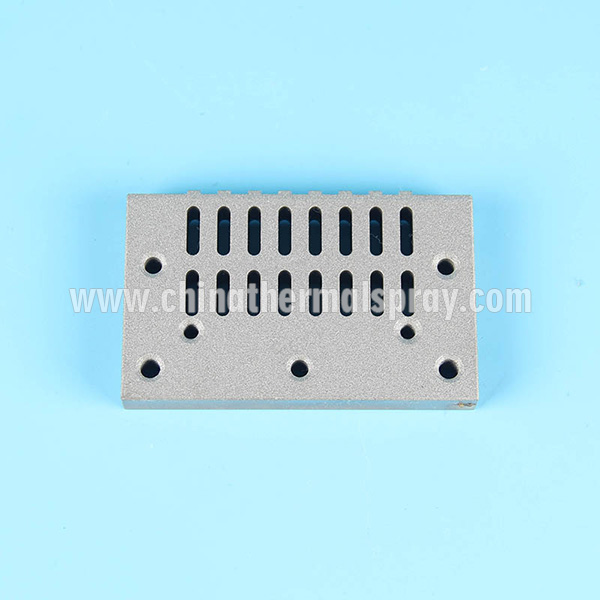

Anti-Sticking Wear-Resistant Coating

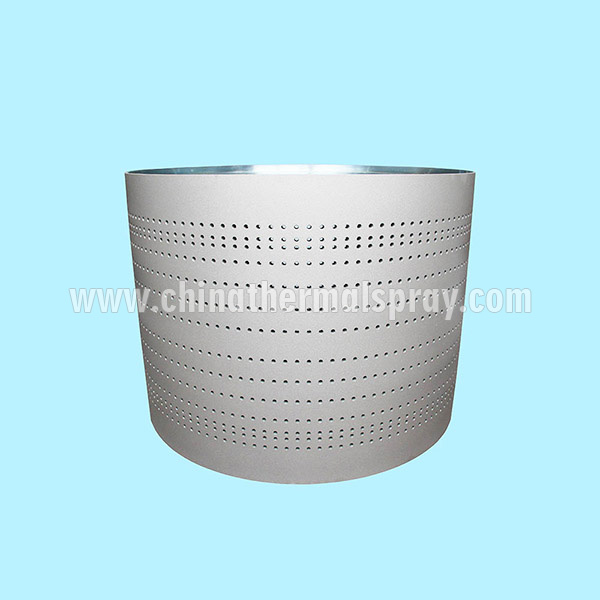

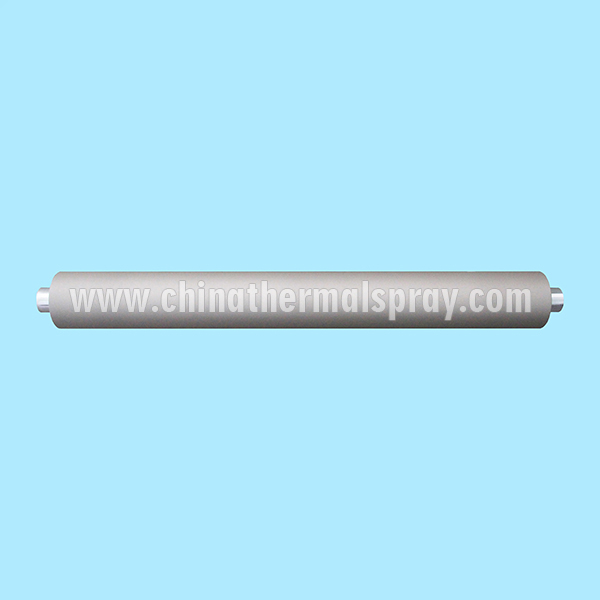

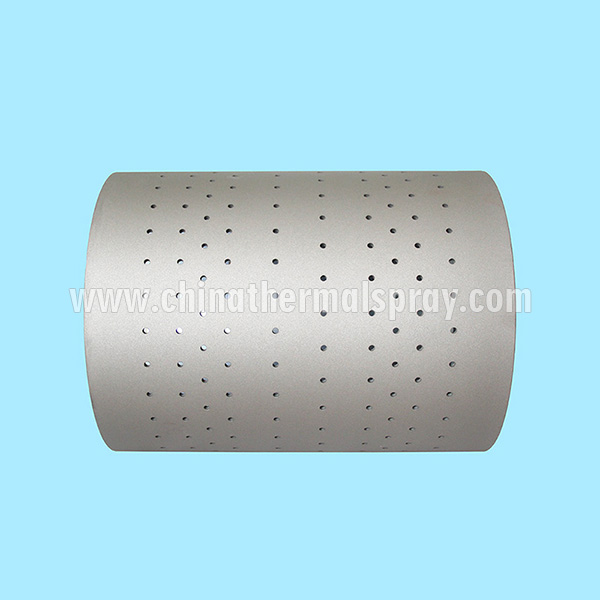

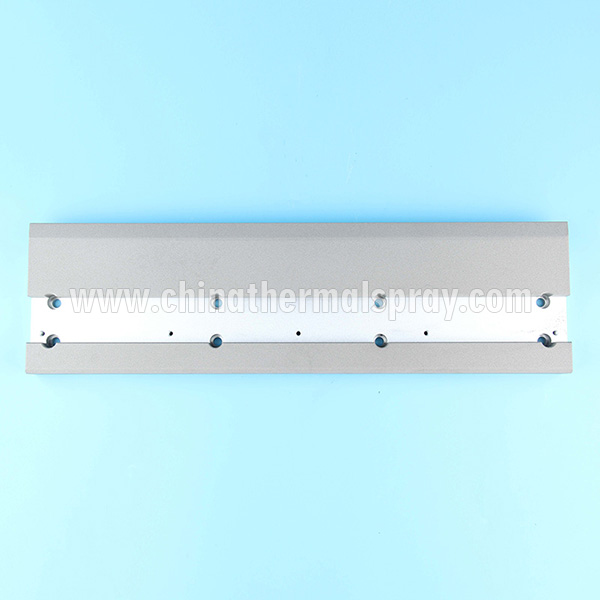

Mainly used in coating machines, printing machines, printing and dyeing machines, tape production machinery, diaper production machinery and other transmission rollers.

Mainly used in coating machines, printing machines, printing and dyeing machines, tape production machinery, diaper production machinery and other transmission rollers. Usually, some drive rollers of these equipments need to contact the glued surface, printing surface or printing surface, and the undried printing surface and printing surface are easy to contaminate the roller and affect the surface pattern of the product.

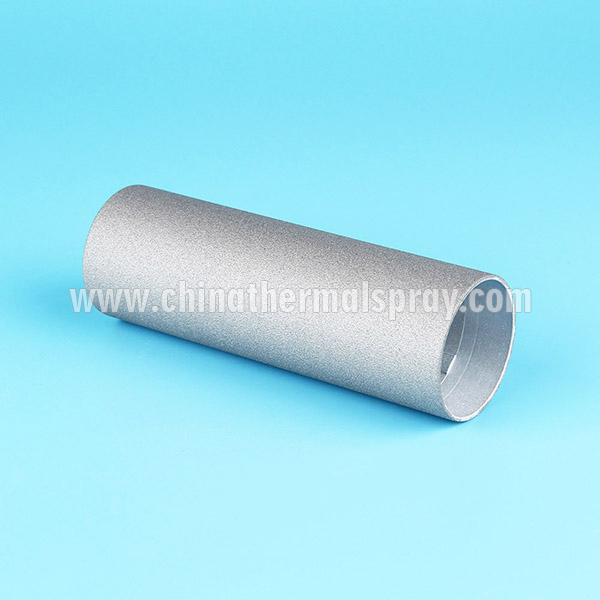

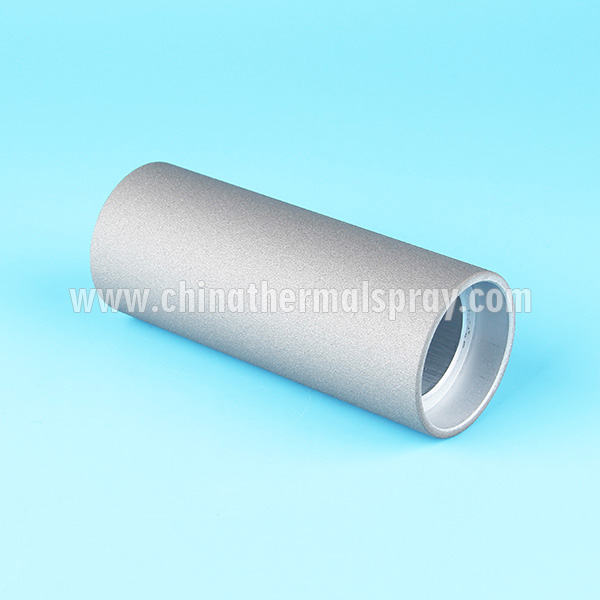

Stripping strength of traditional anti-sticking coating "Teflon" is too strong for hot melt adhesive. That is the anti-sticking performance and wear-resistance is not too good which led anti-sticking performance will lose effect in a short time. It will lead to low production efficiency, short maintenance cycle and high cost.

The invention patent independently researched and developed by our company "thermal spray anti-stick wear-resistant coating" adopts plasma thermal spray technology, uses nickel-based alloy dispersion bond polymer anti-stick material, and uses bionics "Lotus leaf effect", the coating has extremely low adhesive peeling force and excellent wear resistance, and the overall performance is dozens of times higher than that of Teflon coating, reaching the national leading level in this field.

Related products

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

FSH-FMI2020-B Standard Single/Double Channel Fluid Injection

Contact UsFSH – FMI2020 – B standard series of high-precision fluid dispensing / refilling system consists of a digital control box, stepper motor and one to two high precision rotary ceramic pump modules driven by step motor.

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

Reviews

There are no reviews yet.