Hard Surface Wear-Resistant Coating

The coating includes plasma spraying ceramic wear-resistant coating and supersonic flame spraying carbide cermet coating.

Hard Surface Wear-Resistant Coating

The coating includes plasma spraying ceramic wear-resistant coating and supersonic flame spraying carbide cermet coating.

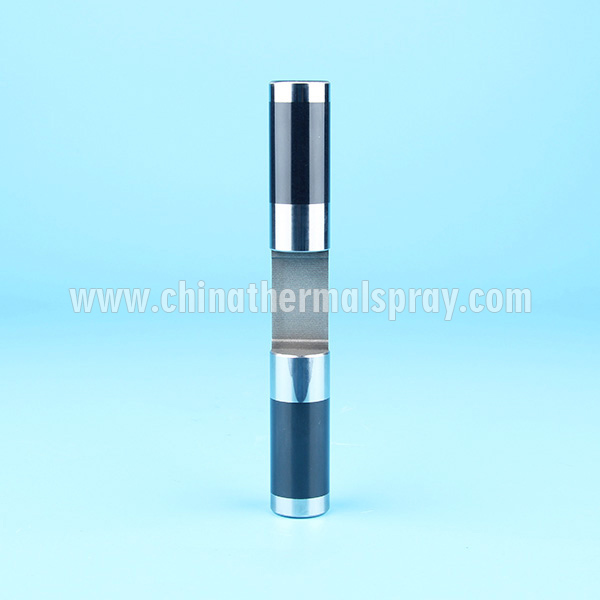

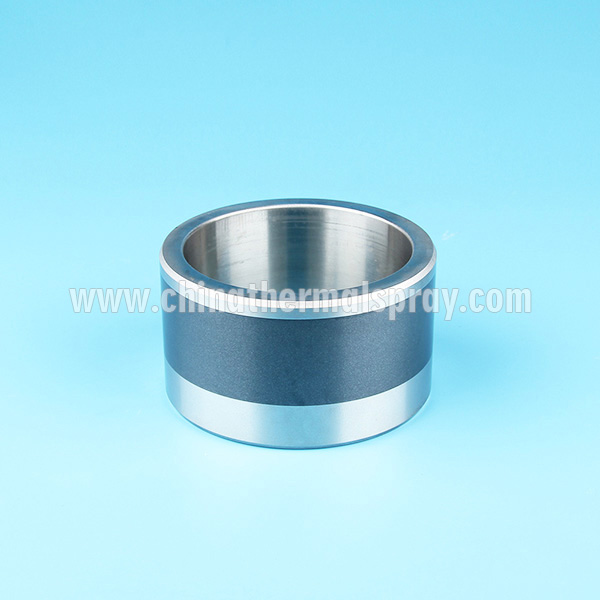

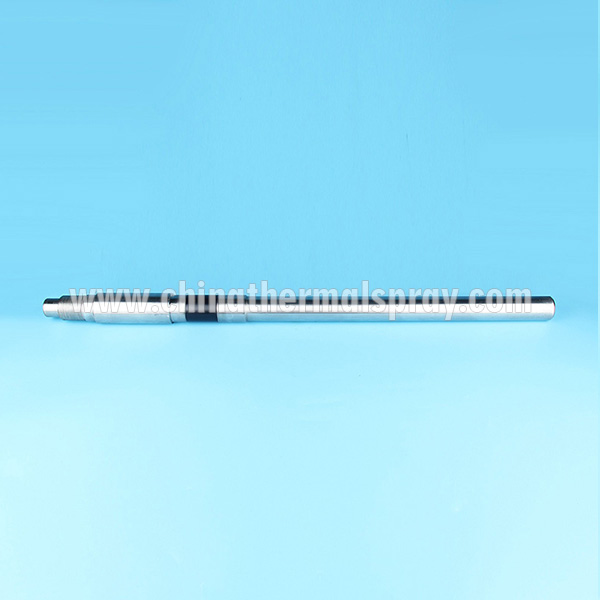

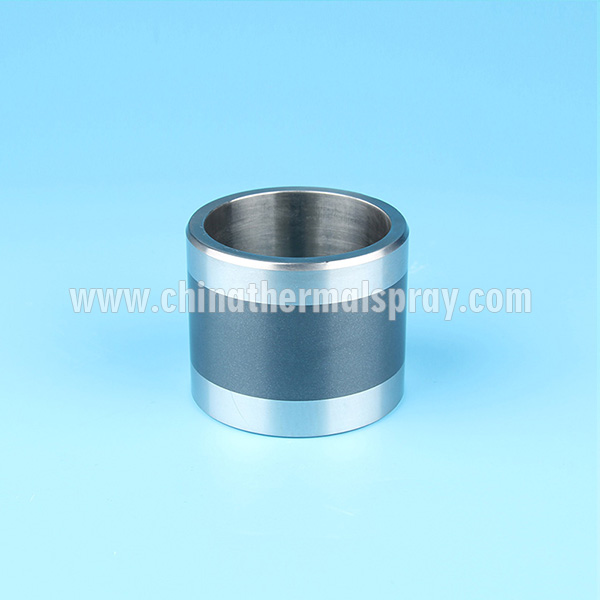

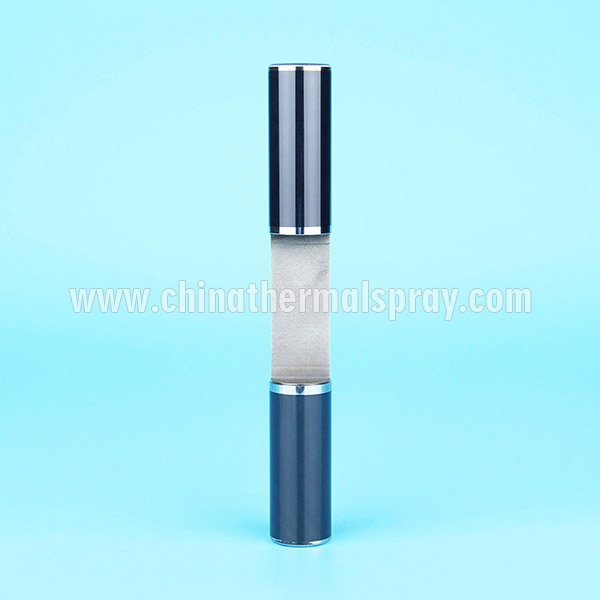

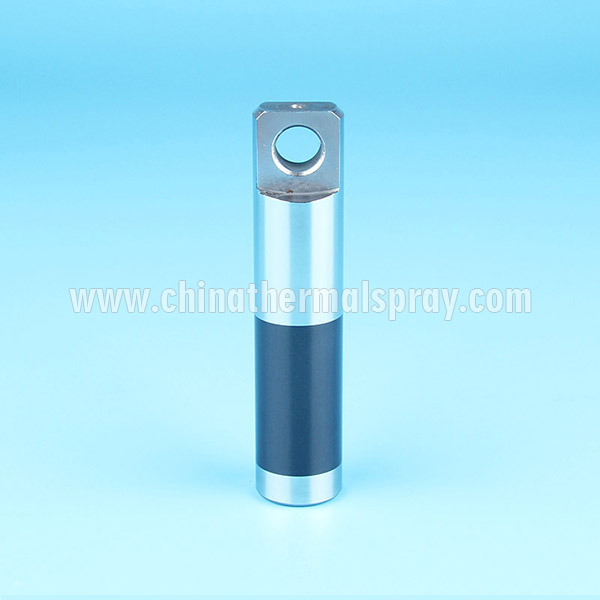

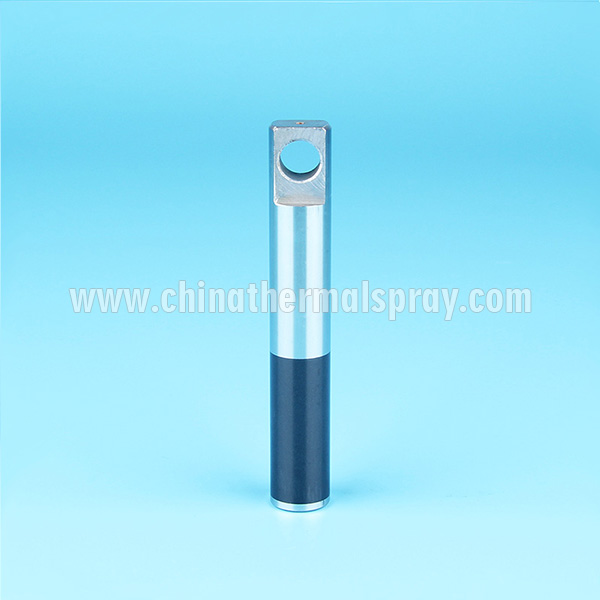

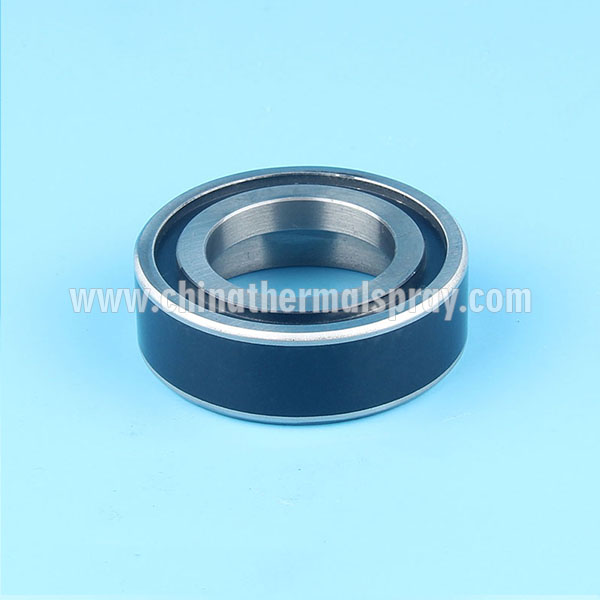

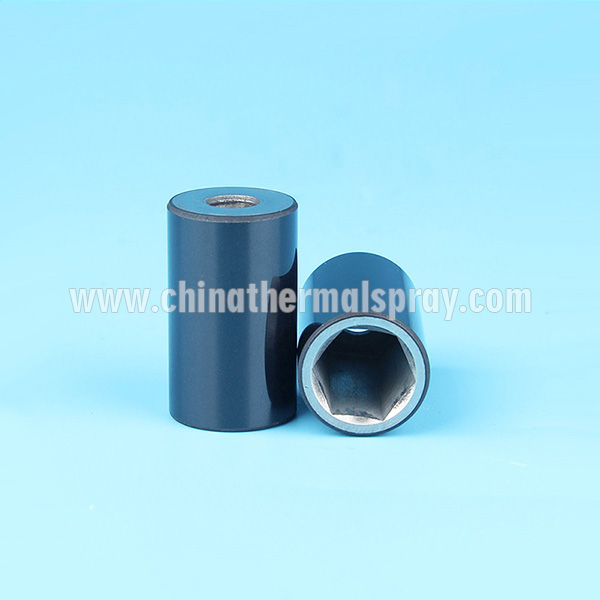

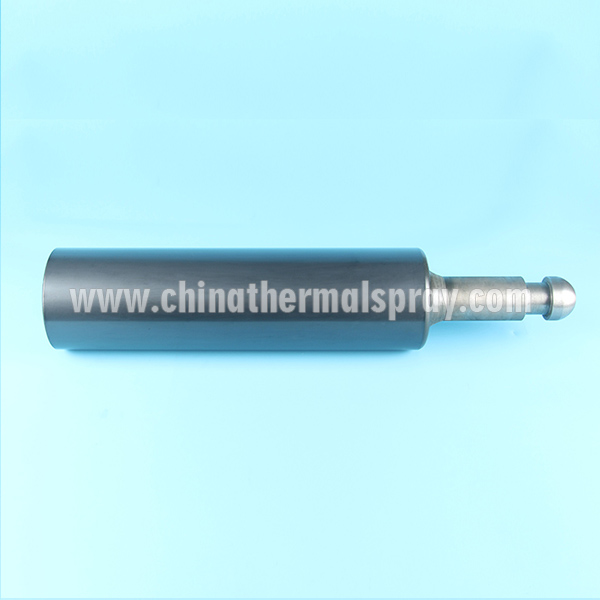

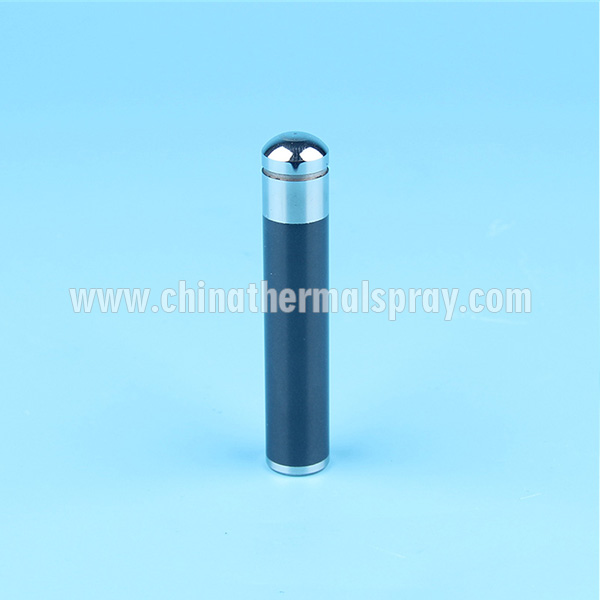

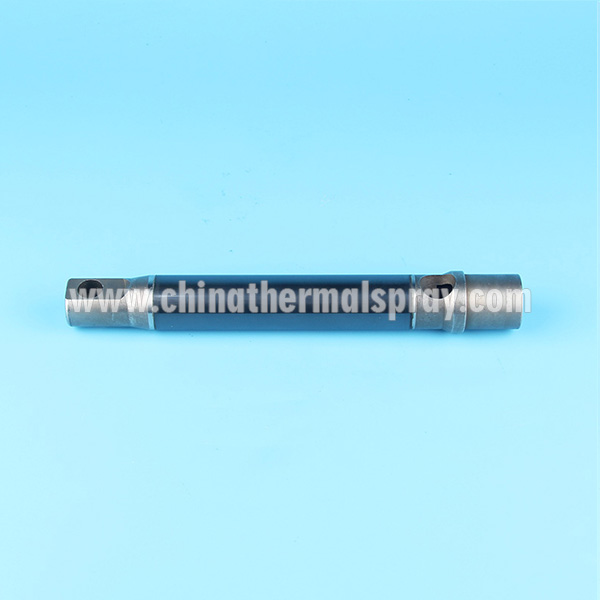

The ceramic materials used in plasma spraying are mainly alumina-titanium/chromia series oxide ceramics. Such materials have outstanding properties such as high hardness, corrosion resistance, good heat resistance, and low friction coefficient. The coating structure is dense, and the surface can be polished to a mirror surface (Ra0.03-0.10 μm). For example, a 0.3-0.5 mm thick ceramic coating is sprayed on the surface of the high-pressure pump plunger, and its service life is 6 longer than that of the conventional hard chrome-plated plunger. times, is the most widely used ceramic coating.

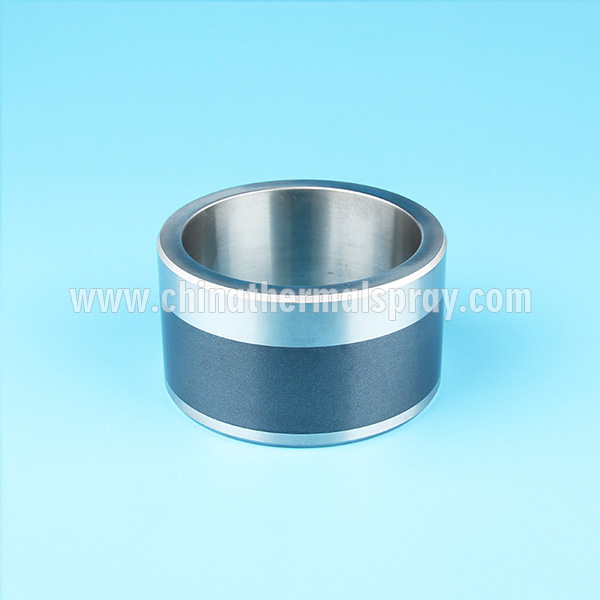

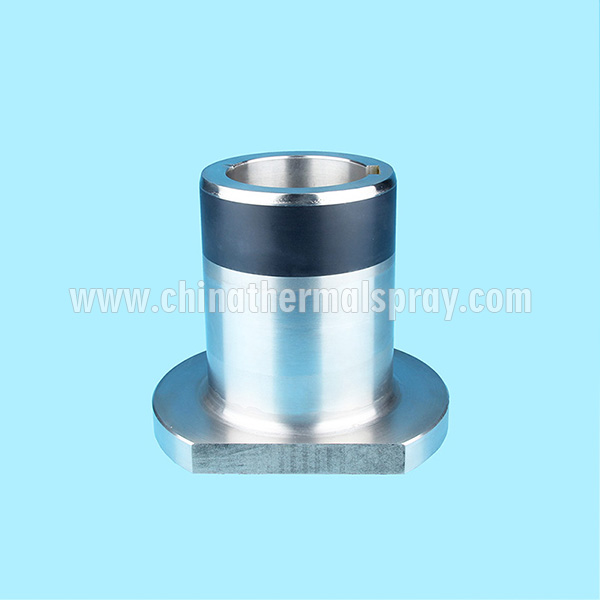

Supersonic flame spraying cermet coating which composites nickel-chrome, cobalt base metal phase and tungsten carbide, chromium carbide etc. hard phase ceramic materials, has the characteristics of high hardness, good toughness and shock resistance etc. Its bonding strength can reach 50-80MPa.

Application:

Plunger pump plunger, high pressure cleaning machine plunger, agricultural sprayer plunger, various water seal oil seal shaft sleeves, various shaft seal sections, etc.

Coating material:

-

AT13 (Al2O3/TiO2 87%/13%): High hardness, good wear resistance.

-

Cr2O3: High hardness, low friction coefficient, good corrosion resistance, abrasive wear resistance.

-

Co-WC: Good high temperature red hardness, abrasive wear resistance, erosion resistance.

-

Ni-WC: High hardness, high temperature oxidation resistance.

Related products

-

Librids 200/400W Portable Solar Panel,Foldable Solar Panel Charger for Power Station, Outdoor Camping RV Travel,Compatible

Contact UsEnergyGain builds update revolutionary solar panels with breakthrough Aramid Fiber (most used in body armor) and housed in robust structure.

-

Librids Mobile Chassis with 1kWh Battery Pack for Modular Power Station Home Use Solar Generator System

Contact UsThis modular energy storage chassis features a 1037Wh, 48V battery pack, perfect for mobile energy needs.

-

01072-081-HS25 Series Incremental Encoder-BEI sensors

Contact UsHS25 combines the rugged, heavy-duty features usually associated with shafted encoders into a hollow-shaft style. Its design includes dual bearings and seals for up to IP65 environmental ratings…

-

Carbon Fiber Sheet

Contact UsCarbon fiber board is a high-performance composite panel primarily reinforced with carbon fibers and cured using a resin matrix (such as epoxy resin).

Reviews

There are no reviews yet.